Decaf Coffee: The Origins & Decaffeination Process

To chemists, caffeine is known as C8H10N4O2; it's a methylxanthine, a central nervous system stimulant. To the rest of us, it's usually just a morning necessity, the buzz in the cup that we need to wake up and get going.

But there are times in our lives when caffeine isn't our friend, and we need to reach for 'decaf,' a word often spoken with a mix of dread and derision. Fortunately, for anyone who has decided to cut back on the kick-in coffee, decaffeination has come a long way.

Decaffeinated coffee is strictly regulated, and the international standard requires that 97% of the caffeine be removed for coffee to be labeled 'decaf.' All decaffeinated coffee is processed at the unroasted or 'green' stage and follows strict safety standards.

The Origins of Decaf Coffee

The first person to decaffeinate coffee was German coffee merchant Ludwig Roselius. In 1903, Ludwig and his team were faced with a shipment of green (unroasted) coffee which had been caught in a storm and soaked in brine.

PHOTO: LUDWIG ROSELIUS | INFOGRAPHIC: WATER DECAFFEINATION PROCESS.

In an admirable attempt to turn lemons into lemonade, Ludwig decided to use this ruined stock in an experiment to remove the caffeine from his salty cargo. He was successful to a degree, using benzene to bond with the caffeine then boiling the bonded solution away.

Unfortunately the flavour boiled away with it, so while it was definitely decaffeinated, it was not particularly drinkable. It was discovered later that benzene is a carcinogen, so the Roselius Process was abandoned.

So no more chemicals? Not quite. Ludwig’s work was not for nothing – safe chemicals have been found that are able to do the same job. The most common solvents used in chemical decaffeination are methylene chloride and ethyl acetate.

How is Caffeine Removed from Coffee?

To achieve decaffeination, the unroasted coffee is first steamed until soft, before being rinsed repeatedly with the chemical over a period of around ten hours, then steamed again to remove the solvent, and dried until the beans become hard again.

If the decaf you are purchasing doesn’t have a method named, it’s probably been decaffeinated this way. Sometimes decaf created using ethyl acetate is labelled as “natural decaf” because ethyl acetate occurs in fruit such as apples.

This is a bit of a misnomer however, as the ethyl acetate is nearly always a synthetic version. Either way, both methods are considered safe by EU, USA and AUS food safety bodies.

What about Water Decaffeination?

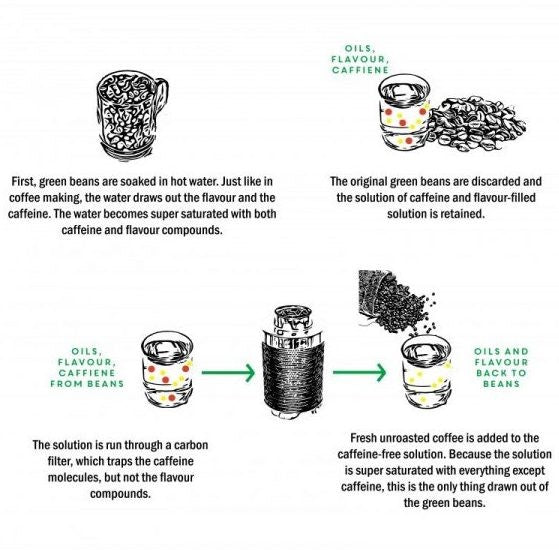

The science of water decaffeination, also know as the Swiss Water Process, is an innovative and environmentally friendly method for removing caffeine from coffee beans while preserving their flavour and aroma.

This process is what's used for the decaffeinated green bean we purchase here at Merlo. The process utilises the principles of solubility and osmosis to selectively remove caffeine from coffee beans. It does however have to be done very carefully to be both low on buzz but high on flavour.

Water Decaffeination Process: Step by Step

Green Coffee Beans: The process begins with high-quality, green coffee beans. These beans are unroasted and contain caffeine, along with a wide range of flavour compounds that give coffee its distinctive taste and aroma.

Preparation: The green coffee beans are first soaked in hot water to dissolve the caffeine and flavour compounds on the outer layers of the beans. This initial step is called "pre-wetting."

Caffeine Extraction: The caffeine-rich water, now containing caffeine and some flavour compounds, is separated from the coffee beans and passed through an activated carbon filter. This filter is specially designed to capture caffeine molecules while allowing the smaller flavour compounds to pass through.

Decaffeination: The caffeine-free water is then used to soak a new batch of green coffee beans. Since the water is already saturated with flavour compounds, it won't dissolve as many additional flavours from the new beans, thanks to the principle of solubility. However, it will still draw out the caffeine, as caffeine molecules are relatively small and easily pass through the coffee bean's cell membranes.

Osmosis: As the new batch of beans is exposed to the caffeine-free water, osmosis comes into play. The caffeine naturally moves from an area of higher concentration (inside the coffee beans) to an area of lower concentration (the surrounding water). This equalises the caffeine content between the beans and the water, resulting in caffeine extraction without significant flavour loss.

Repeat Process: The water is continuously circulated through the system, passing through the activated carbon filter to remove caffeine and then reused to decaffeinate multiple batches of coffee beans. This recycling process minimises waste and helps maintain the integrity of the flavour in the beans.

Drying and Roasting: After decaffeination, the coffee beans are dried to the desired moisture content and then sent to us to be roasted. Our roasting is a critical step that develops the unique flavour profile of each coffee bean. The Swiss Water Process ensures that the decaffeinated beans retain as much of their original flavour as possible.

Quality Control: Throughout the entire process, strict quality control measures are in place to ensure that the coffee beans meet the desired flavour and aroma standards. Our Q-Grader and Roasting team regularly evaluate the beans to maintain their high quality.

The Swiss Water Process is highly regarded for its ability to produce decaffeinated coffee with minimal flavor loss. It is a preferred choice for those who want to enjoy the taste of coffee without the stimulating effects of caffeine.

Additionally, this method is considered more environmentally friendly than some other decaffeination processes that use chemical solvents, making it a popular choice among coffee producers and consumers who value sustainability and purity.

Try our Decaf Coffee HERE.