New San Jeronimo de Naranjo from Costa Rica

In the world of specialty coffee, a limited edition gem emerges from the heart of Costa Rica - San Jeronimo de Naranjo. With a captivating...

Just Chill – the perfect drop for hot days

Our ‘Just Chill’ range offers a variety of eight delicious frappe flavours and an iced cappuccino to help you cool down on hot summer days....

Decaf Coffee: The Origins & Decaffeination Process

What process do green beans have to go through to be classed as decaffeinated coffee? And are all 'decafs' created equal? Get the downlow on...

Wine and Chocolate Can Go... But Coffee is a Must!

We would give up wine and go without television, but most Australians could never forgo their daily caffeine fix, according to a new survey. More...

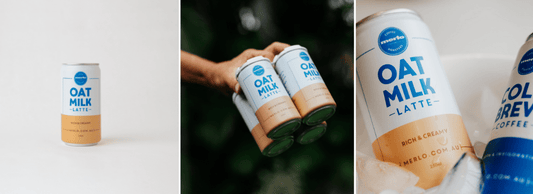

Merlo Coffee Oat Milk Latte

Iced coffee lovers rejoice: our Cold Brew cans have a new addition – the Merlo Coffee Oat Milk Latte. Developed specifically for discerning coffee lovers...

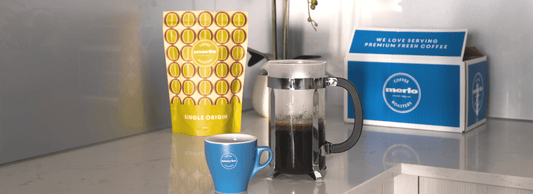

Secrets to Making Amazing Plunger Coffee: A Step-by-Step Guide

Learn how to make great plunger coffee at home with our brew guide. The plunger is a simple way to prepare coffee at home and...

15 Different Types Of Coffee Drinks Explained

If you’ve always been too shy to ask your barista the difference between a flat white and a latte, then this article is for you.

Merlo Cold Brew available instore!

We are excited to announce the launch of our new Merlo Cold Brew cans, now available for purchase in all of our Merlo-owned locations.

AeroPress or AeroPress Go - which one is best for you?

AeroPress v AeroPress Go - which one is best for you?

How make great coffee with a Chemex

Learn how to brew a pure, smooth tasting coffee with a Chemex – one of the best designed products in modern times.